It’s no secret that the current economic climate has left factories and businesses in a tight spot. While this is partly due to external factors like the recession and growing global competition, it’s also being driven by laws that are designed to increase transparency and protect consumers from unfair business practices. The German Act on Corporate Due Diligence in Supply Chains which came into effect at the beginning of this month is one such example of this.

It is designed to make the country’s manufacturers more efficient and accountable in their supply chains. However, with its implications for manufacturing even trickier to understand than most people might expect, we take a look at what it means for everyone in the supply chain ecosystem.

What is the German Supply Chain Due Diligence Act?

The German Act on Corporate Due Diligence in Supply Chains is a piece of German law that was passed in 2021 and came into affect on 1st January 2023. As its name suggests, the law focuses on improving supply chains in the country. This means that companies will now be required to investigate the ethics and practices of their suppliers and manufacturers as a means of ensuring they’re not skirting around any regulations that might be relevant to their business. It also means that companies will now be required to identify their external suppliers, to a certain extent.

What does the German Supplier Due Diligence Law mean for your company?

If you manufacture or supply products in Germany, then the German supplier due diligence law will likely impact your business. Given that the law is directly related to increasing transparency and holding your stakeholders accountable, it’s not surprising that the law is so critical for German manufacturers.

The German Act on Corporate Due Diligence in Supply Chains will require you to complete supplier due diligence (SDD) on your external suppliers. The key question is what does “supplier” means in this context? The law defines a supplier as any business that provides goods or services to your company, either directly or via other businesses. This might seem like a small distinction, but it can have major implications for your organization. Let’s say you outsource some aspects of your business, but you also maintain control over these parts.

The supplier due diligence law would still apply to these outsourced functions. This would mean you would have to investigate the ethics of your suppliers to ensure they’re not skirting around the same regulations that apply to you.

Why is this law so important for manufacturing in Germany?

Germany is a global powerhouse when it comes to manufacturing – and it’s not hard to see why. These are some of the factors that make Germany such an attractive manufacturing location:

Friendly legal system

The German legal system has long been seen as a favorable one for manufacturers, thanks to its emphasis on contractual agreements. That’s why many companies and investors look to Germany as a key location for manufacturing expansion.

Advanced technology

Germany has an advanced technology sector that’s considered among the best in the world. As a result, Germany is often a top choice for manufacturers looking to expand their technology capabilities.

High-quality products

Consumers in Germany expect high-quality products, and the country’s domestic market ensures this. That’s another key consideration for manufacturers, as it means a higher level of demand than what you’d see in a country like the US.

Things to consider before implementing a supply chain due diligence program

There are a number of factors you’ll need to consider when implementing a supply chain due diligence program. These include things like the type of products and services you sell, how complex your supply chain is, and how much time you’re willing to spend on this process.

Given these factors, you’ll want to make sure you spend time on the following elements of supply chain due diligence:

Having an accurate inventory of your suppliers

You’ll want to make sure you have an accurate inventory of your suppliers, and that you know who they are and the relationship between them and your business.

Having an accurate picture of your supply chain

This includes how many products come out of each supplier, and how far they are along the supply chain. It’s also important to make sure you have an accurate picture of the product’s specifications, as this will help you identify any potential risks early on.

Understanding any ESG risks within your supply chain

In our experience, one of the biggest challenges companies face within their supply chains apart from the obvious logistical problems is the possibility that there are environmental or human rights violations taking root within the supply chain unnoticed or until it is too late and results in a PR disaster. When a big environmental or human rights violation breaks in the news it can cause unparalleled brand and reputation damage.

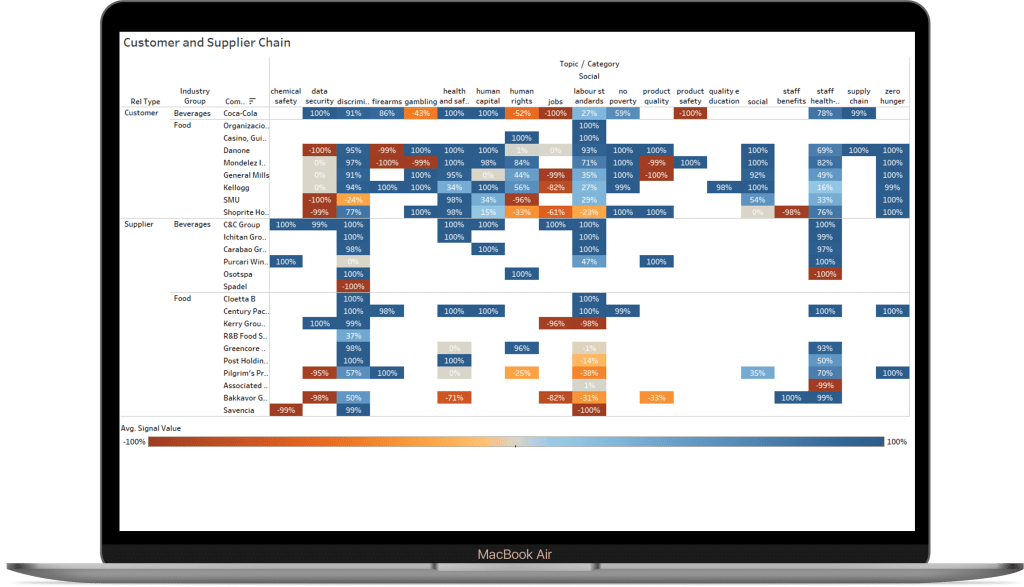

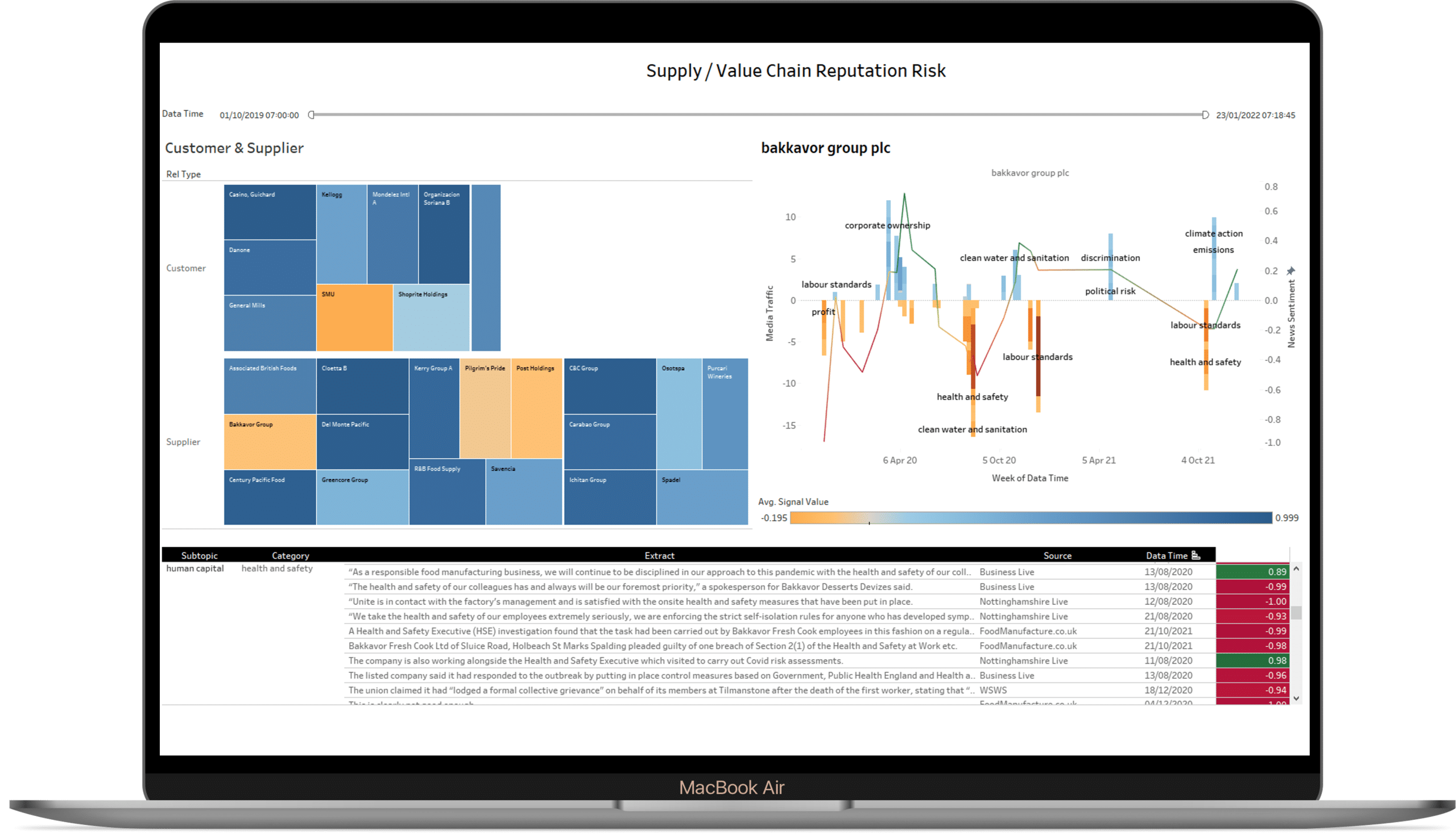

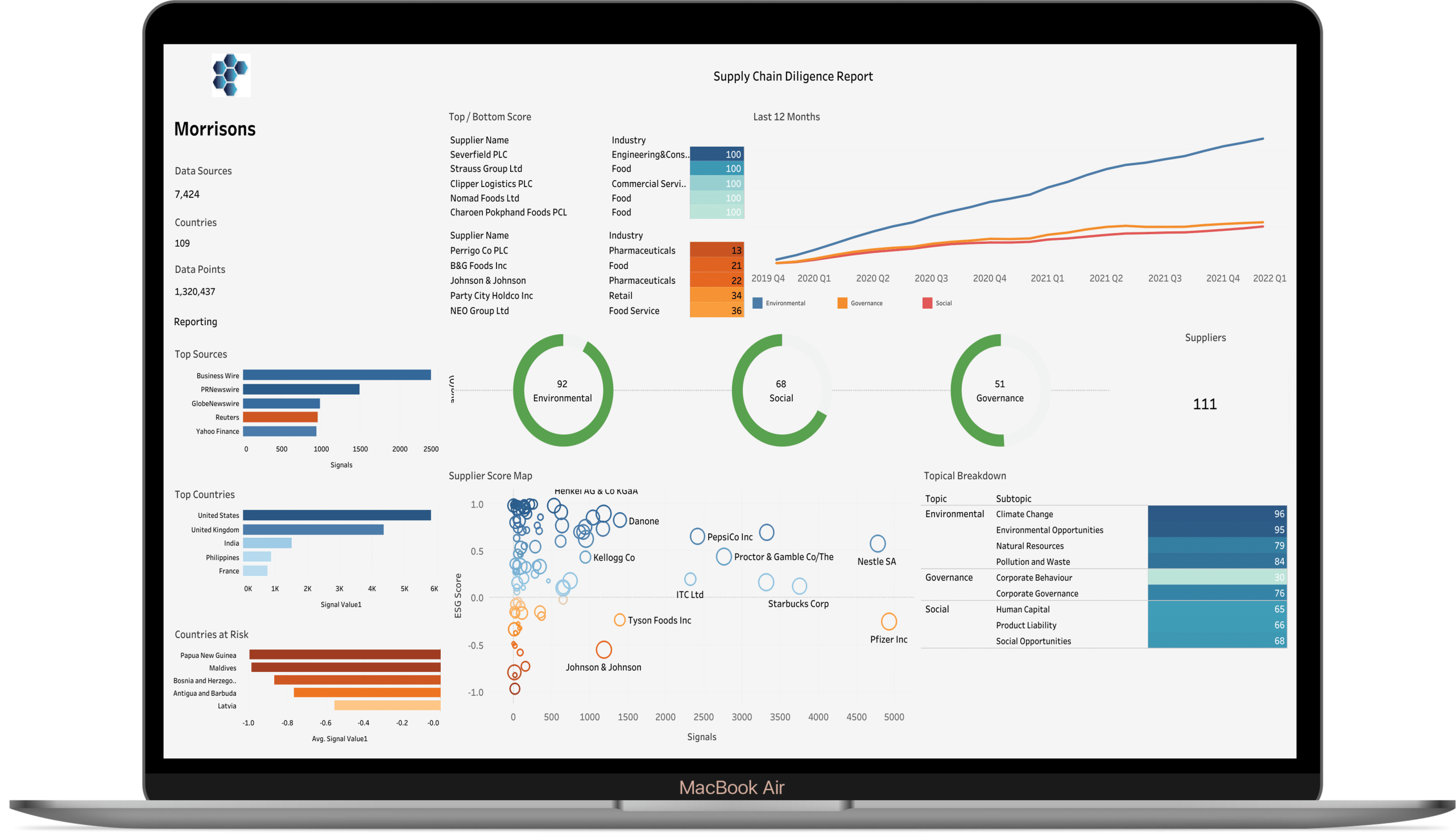

At Permutable, we use real-time machine learning-driven analysis of global news flows to provide an ongoing view of ESG risks across our client’s supply chains. The data is made available instantly allowing clients to act fast on any ESG risk factors and comply with constantly evolving ESG and due diligence legislation.

Assessing the quality and safety of your products

Another important part of supply chain due diligence is assessing the quality and safety of your products. This involves taking samples of the products and sending them off for testing to ensure you have a comprehensive picture of their safety.

Navigating this process effectively

While the supply chain due diligence process can be frustrating and time-consuming, there are a few things you can do to make it a bit easier. These include things like:

Conducting a traceability analysis

A traceability analysis is an important part of supply chain due diligence. This involves tracing all of your products back to their origins, and will help make sure you identify any issues with your products’ origins early on.

Identifying any potential issues are early on as possible

Conclusion

The German Act on Corporate Due Diligence in Supply Chains is a serious law that’s designed to increase transparency in the country’s manufacturing sector. If you manufacture products in Germany, then you’ll need to undergo supplier due diligence to ensure your external suppliers are adhering to the highest standards. While this law was designed to improve the German manufacturing industry, it can also be implemented by any company in the supply chain ecosystem. That means everyone from manufacturers to retailers and service providers can benefit from its benefits. Given that, it’s likely to become an even more important part of the manufacturing ecosystem moving forward.